New AeroDieCut Application: Coasters Showcasing Six Finishing Techniques

We are pleased to present a new application for our AeroDieCut — a set of coasters designed to demonstrate six different finishing techniques simultaneously.

In Japan, where “oshi-katsu” (supporting favorite characters or idols) continues to grow in popularity, printed items such as coasters have become highly demanded and profitable. This coaster series creatively showcases the diverse processing capabilities of the AeroDieCut.

Paper used: GA FILE White 310kg (530 μm thickness), 320×450mm Y grain, provided by TAKEO Co., Ltd.

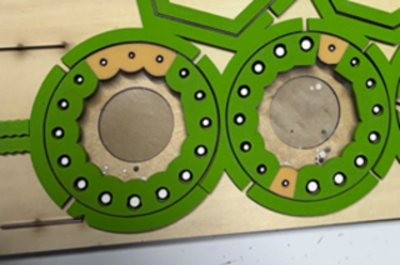

1. Coaster with Punch Holes

Circular holes range from 1 mm to 5 mm in diameter, increasing in 0.5 mm increments. Thanks to the die-board design and AeroDieCut’s unique imposition control function, punched waste is automatically removed — no manual stripping required. Holes of 1–2 mm are commonly used on accessory display cards.

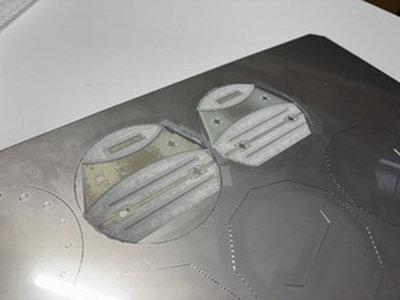

2. Simulated Embossing Using Creasing Rules

Instead of using traditional embossing plates, this method pairs creasing rules with a counter plate (pertinax) to create a simulated embossing effect. It enables more cost-efficient die-board production.

3. Coaster That Doubles as a Display

A central crease and cut line allow the coaster to function as a mini display stand. Originally designed for restaurants and cafés to indicate reserved seating, it can also showcase favorite items for “oshi-katsu” collections. The outer edge is cut with a wave rule, reducing the risk of paper cuts.

4. Coaster with Decorative Slits

Decorative slits of 5 mm and 10 mm add visual interest to the coaster. Even these fine shapes are cut cleanly, demonstrating the precision and versatility of the AeroDieCut.

5. Perforated Design

Two concentric perforation lines create a decorative leather-like look, especially when laminated.

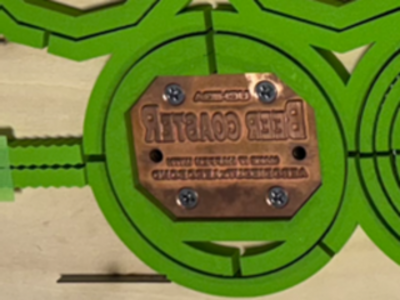

6. Debossed Lettering

A metal plate embedded in the die board produces debossed lettering, adding a premium tactile feel.

All coaster outlines except item No.3 are cut using NOZOMI micronic rules from Nakayama Corporation, designed to minimize nicks and make waste stripping easier.

This coaster application is an excellent example of how AeroDieCut can demonstrate multiple processing techniques in a compact, engaging format. We look forward to exploring further creative applications and welcome suggestions from our customers and partners.