New Application of AeroDieCut: Braille-Embossed Medicine Boxes

A New Application of AeroDieCut: Accessible Packaging for All

As accessibility standards continue to expand globally, pharmaceutical packaging must increasingly incorporate Braille information. With AeroDieCut, both Braille embossing and die-cutting can be handled with precision and flexibility—improving setup efficiency and production stability.

This article explains how AeroDieCut is used to produce Braille-embossed medicine boxes.

Paper Specification

For this application, the following paper was used:

- Type: Coated paper

- Size: 320 × 450 mm (SRA3)

- Weight: 310 gsm

Two-Step Workflow: Braille Embossing & Box Cutting

To improve plate reusability and maintain stable embossing quality, the process was divided into two steps.

Step 1: Braille Embossing

Braille was embossed in two separate positions per sheet. Using AeroDieCut’s Imposition Control Function, the system performs two precise presses on a single sheet—one for each box area.

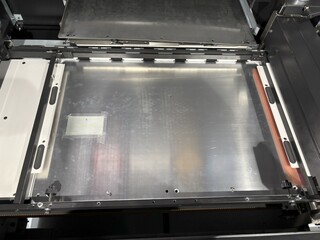

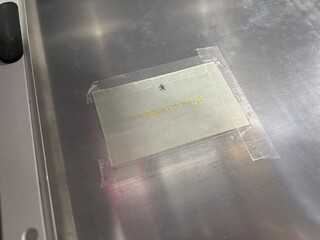

Embossing Plate Setup

Plate size (male & female): 82 mm (W) × 50 mm (H)

Male (convex) plate:

Material: Resin-based

Mounted on the cutting plate

Female (concave) plate:

Structure: Etched copper plate (3 mm) mounted on aluminium block (19.6 mm), total thickness 22.6 mm.

Mounted on the die-board side using an optional adapter.

Note: The die-board adapter shown in the video is from a previous model. The current version may differ in design.

By separating the embossing step, Braille plates can be reused efficiently, making setup faster when switching between different jobs.

Step 2: Die-Cutting the Box Shape

After embossing, AeroDieCut die-cuts each sheet into two medicine box blanks.

One-Pass Processing Also Supported

Alternatively, Braille plates can be embedded directly into the die board—performing embossing and die-cutting in a single pass. This method is ideal for streamlined, high-volume production.

Customer Case Study: Artrema (Lithuania)

Artrema, a packaging manufacturer based in Lithuania, uses AeroDieCut to produce Braille-embossed medicine boxes. In the video below, they explain how the system has improved their production workflow and efficiency.

Contact Us

If you’d like to learn more about AeroDieCut or its applications for Braille embossing, please contact us:

sales@uchidayoko.com