Application

Full-Cut and Half-Cut in a Single Pass Using UCHIDA AeroDieCut

Precision Die-Cutting Meets Creative Design

In this case study, we showcase how AeroDieCut enables high-precision processing of both full cuts and half cuts within a single workflow. Using adhesive paper made with YUPO, a synthetic material produced by YUPO CORPORATION, we produced custom stickers with vibrant color, clean outlines, and a professional-grade finish—all in one smooth process.

Project Overview

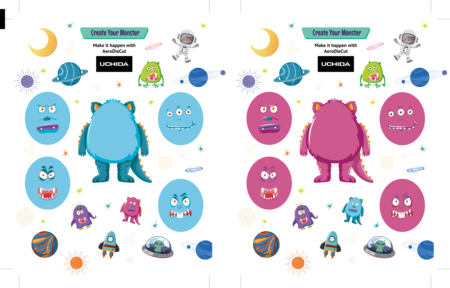

<Artwork>

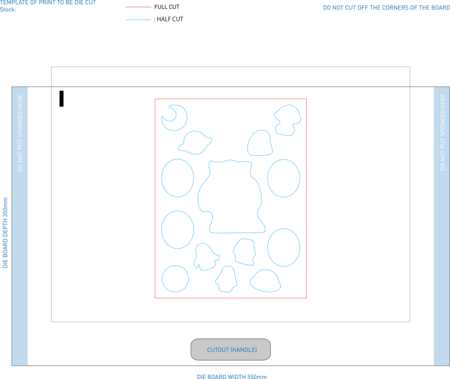

【Die-Cutting Setup】

- Die board size: 330 × 550 mm

- Sheet size: 320 × 450 mm

- Cutting plate material: Stainless steel

- Die Blade Coating: The die board was treated with a silky coating to reduce adhesive buildup and maintain clean results during extended runs.

【Material Details】

- Surface material: YUPO (synthetic paper)

- Surface material thickness: Approx. 110μm

- Release liner thickness: Approx. 160μm

<Dieboard diagram>

Dual Cutting Depth with a Single Die Board

In this project, we performed two types of cuts in a single pass using one die board:

- Full cut (outer contour, red): Blade height 23.6 mm

- Half cut (inner decorative shapes, blue): Blade height 23.44 mm

(The 0.16 mm difference accounts for the thickness of the release liner beneath the adhesive paper.)

This setup allowed for precise and efficient cutting without changing dies or adjusting the machine, making the process faster and more consistent.

Additionally, we utilized AeroDieCut’s Imposition Control function to perform two presses on a single sheet using one die, creating a 2-up layout.

This enhanced production efficiency and helped reduce the cost of die board fabrication.

Improved Workflow with the updated optional accessory, Waste Separator

This demonstration also featured AeroDieCut’s optional Waste Separator, designed to assist with clean and reliable removal of cut waste. It helped streamline post-processing and improve overall handling—especially valuable for adhesive-backed materials.

Supporting Diverse Materials and Applications

While this case utilized YUPO-based adhesive paper, AeroDieCut is versatile and can handle a wide variety of materials. This flexibility, combined with its precision, makes it an excellent solution for custom sticker and label production, as well as other applications requiring accurate, high-quality die-cutting.

Contact Us

If you are interested in trying AeroDieCut with your preferred materials or would like support with die design and production planning, feel free to reach out.

Our team is here to help turn your ideas into reality—with precision, efficiency, and confidence.